Challenges

In agriculture industry, product sorting was conducted according to size and weight.

The customer who produces cherry tomatoes sorted out by hand.

Since cherry tomatoes are fragile and there are many ranks of sizes, sorting out a large amount of cherry tomatoes took time, which led some cost increase and work inefficiency.

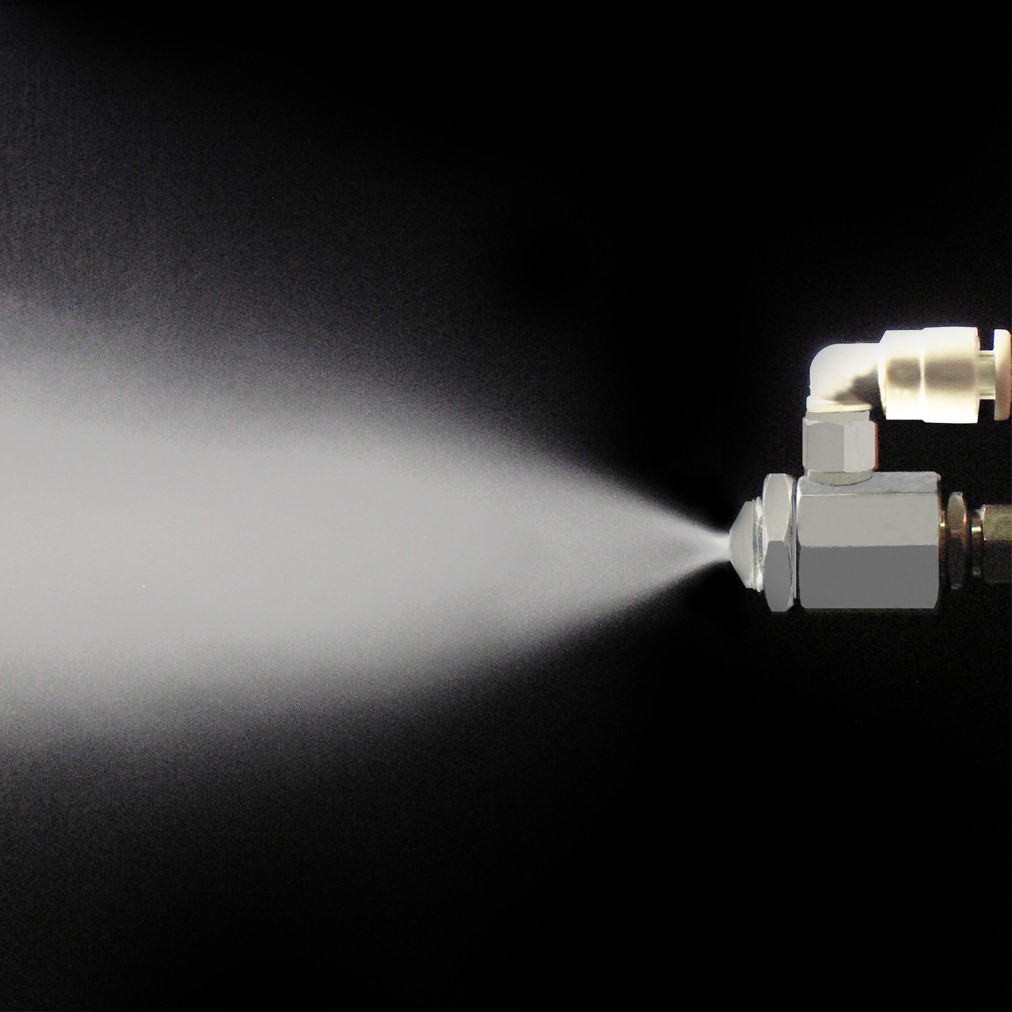

For the cost reduction and work efficiency improvement, the customer was developing an automatic sorter, considering an air jet nozzle for sorting.

Solution

The ranks of cherry tomatoes were sorted out by a sensor. After that, various air jet nozzle blow out cherry tomatoes according to the rank.

Optimal air jet nozzle was necessary because of various size of cherry tomatoes.

Trial

Test of the air jet nozzles was conducted with a prototype sorter and an optimal air jet nozzles to sort out each rank of cherry tomatoes was selected.