Challenges

The previous painting nozzle had high cost and the lead time was long.

In addition, the customer purchased an inner parts called restrictor.

Its diameter varies widely and this had a negative influence on spraying.

Therefore, the customer was planning to change the manufacturer of not only the spray nozzle but also the restrictor.

Solution

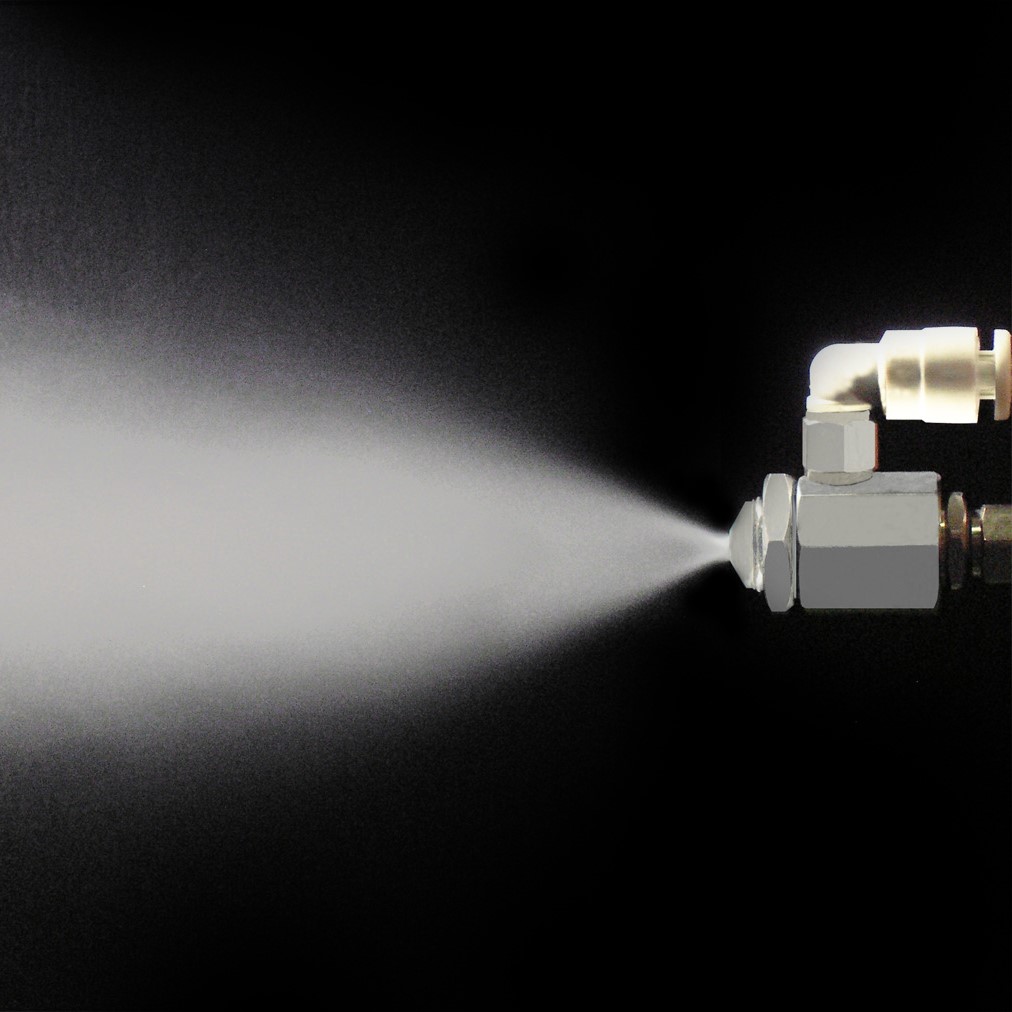

Our proposal was for short lead time, cost reduction and quality improvement by the optimal spray nozzle.

Also, we proposed variation preventions by not only change of spray nozzle and restrictor but also hard material change for wear prevention on paint spray.

Trial

We designed a prototype nozzle based on the measurement result of spray pattern, spray angle of the previous nozzle.

After repeat of prototyping, the variation was prevented.

Also, we conducted some trials with different materials for wear resistant improvement, And the best material was selected as SUS440C and SKD12.