Challenges

Dialysis filter is medical equipment which removes wastes, surplus water and electrolyte from blood.

In its manufacturing, there is dewatering process after washing.

Previously, dewatering was conducting by hand with a spray gun.

With increase of its demand, the production volume increased, which caused the manufacturing cost increases as the time of dewatering by hand.

In addition, there was an issue of keeping the workforce as well.

In order to the cost reduction and productivity improvement, the customer. as planning a process of automation, was looking for a customized air nozzle which was able to not only dewater but also meet their special header.

Solution

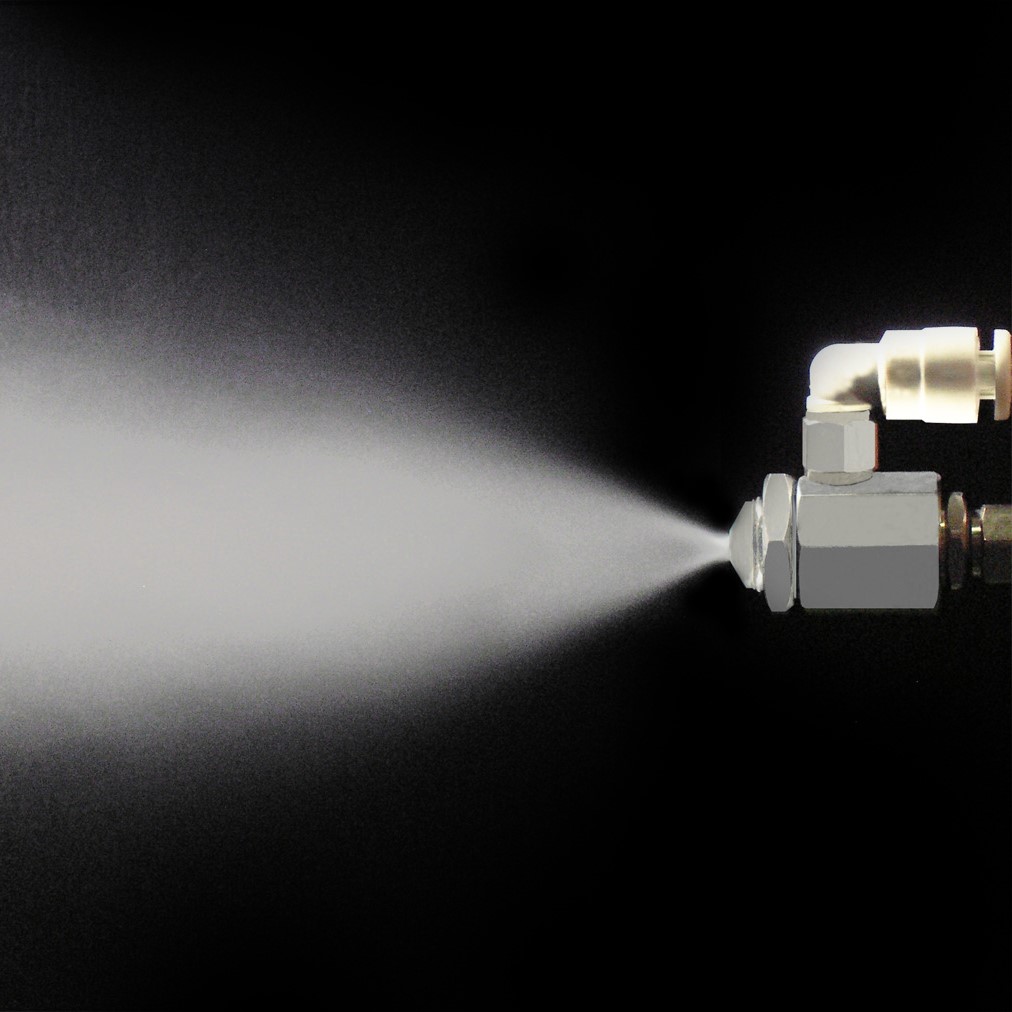

We proposed air jet nozzle which had high impact force with ball joint which was able to change spray direction and ring header.

Trial

We conducted a dewatering test with our customized air jet nozzle in our factory,

The test was conducted with the actual dialysis filter. And, complete dewatering was confirmed by customer.

Therefore, the customer decided to adopt the customized air jet nozzle.