Design & development

Everloy proposes the best solution with design and development service.

-

Hard to meet requested quality...

-

Too difficult to manufacture…

-

No chance for trail...

Contact us!

-

POINT

01Design & development

We have provided the best solution with ourcustomized nozzles based on our long term experience as a spray nozzle maker.

Here are solution cases.

Search from industries

Search from improvement

Search from uses

Search from fluid

-

POINT

02Analysis & evaluation

Finding the issue of conventional products is the first step of improvement. Excellent equipment and technology for analysis and evaluation is essential.

Our analysis of flow rate, spray pattern, flow rate distribution and impact force distribution contribute to our special nozzle design.Equipments & services

-

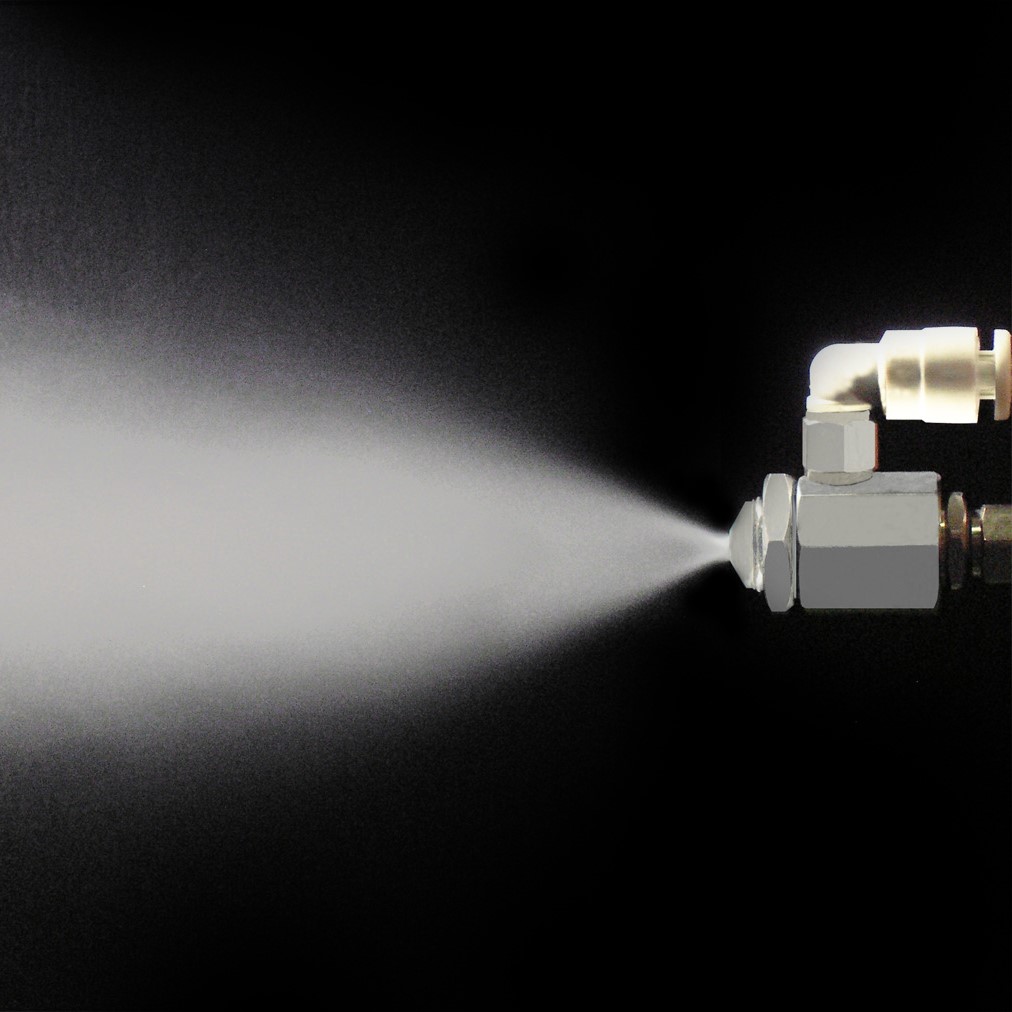

Image analysis method

This system determines average particle size and particle size distribution by image analysis using stroboscope and CCD camera.

-

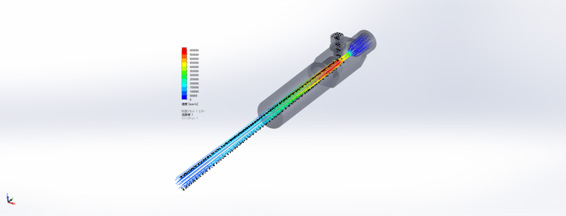

Computational Fluid Dynamics(CFD)

we can visualize actual performance by our well -experienced practice, analysis and evaluation.

-

Flow rate distribution measurement system

This device makes flow rate distribution graph by spraying to acrylic container for specific time.

-

Particle size measurement system

This system is a particle analyzer making use of the phase doppler principle of the laser doppler system to simultaneously measure the velocity and size of particles.

-

Impact force distribution measurement system

This device makes impact force distribution graph by sensor which scans spray continuously.

-

Heat Transfer Coefficient(HTC) measurement system

This system measures HTC by thermal sensors in the plate and cooling performance is evaluated from HTC.

-

-

POINT

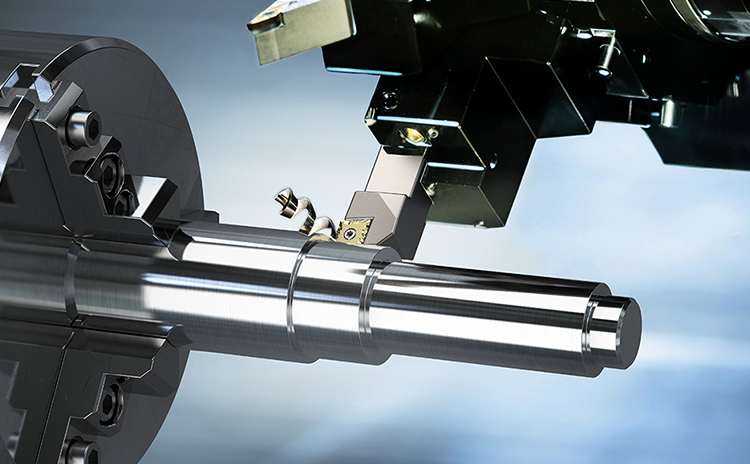

03Prototyping & technology

We prototype special nozzles and test based on customer's request and our analysis and evaluation system.

Specific know-how and technology is required on prototyping.