Challenges

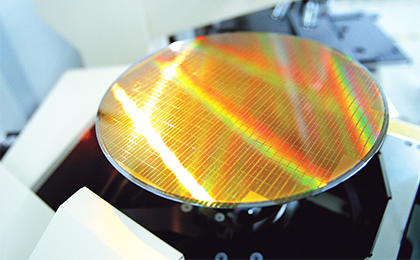

There are various kinds of equipment for semiconductor manufacturing process and cleaning equipment is one of them. Cleaning equipment for silicon wafer is important one as quality is down if it did not work.

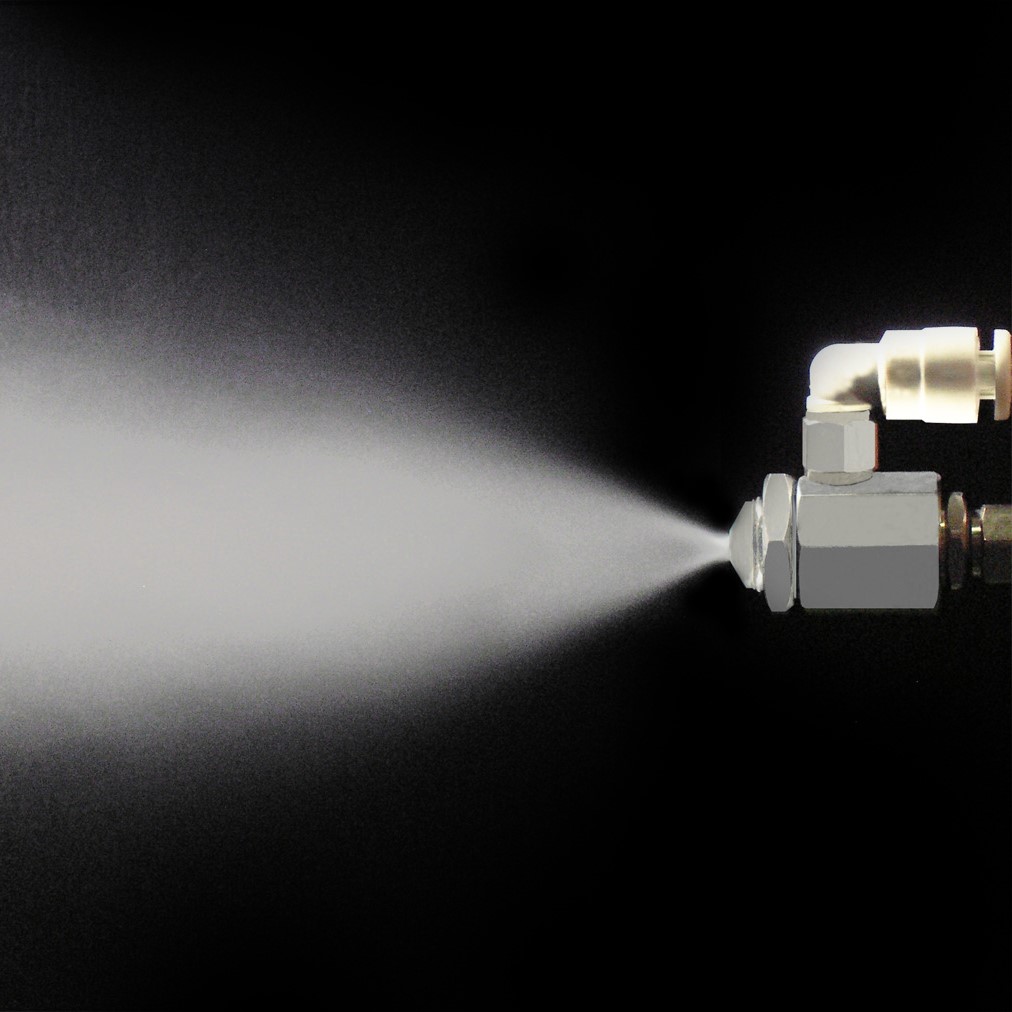

Hydraulic or two fluids nozzle is used for such process by using pure water or chemical.

There are various kinds of foreign materials such as 0.1 micron meter dust, atom of heavy metal, carbon molecule and oil.

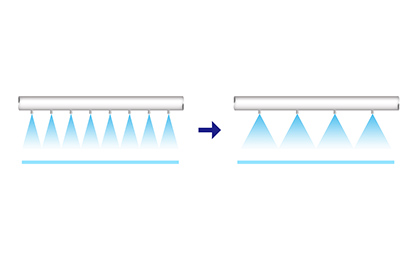

Spray nozzle layout has to be designed with overlapping so it can clean it perfectly, however, a lot of piping goods are also required if nozzle required nozzle quantity was increased which means cost up, it was the biggest issue at designing process.

The customer in this case was demanding to reduce number of nozzles. On the other hand, they were taking care of the risk for washing result when nozzle quantity was reduced.

Solution

We proposed to use the nozzle which is customized spray angle. Although it was the issue which our competitor has declined this issue, We has tried to go to realize both cost down and keep washing efficiency at a same time by optimizing nozzle specification.

Trial

We measured water flow distribution of the nozzle which customer was currently using to figure out the issue which should be concerned. Then we created prototyping spray nozzle by data conversion and designing optimized nozzle layout.

We also figured out the reducing points of impact force when spray angle became wide because spray angle had to be wide to reduce nozzle quantity. After couple of times of repeating trial and error, finally we proposed the nozzle layout with customized nozzle which can realize to keep washing efficiency.