Basic knowledge and selection method of hydraulic spray nozzle

Everloy has been supplying a variety of hydraulic nozzles to all over the world.

You can learn both basic knowledges and selection methods in the hydraulic nozzle from a spray nozzle expert point of view.

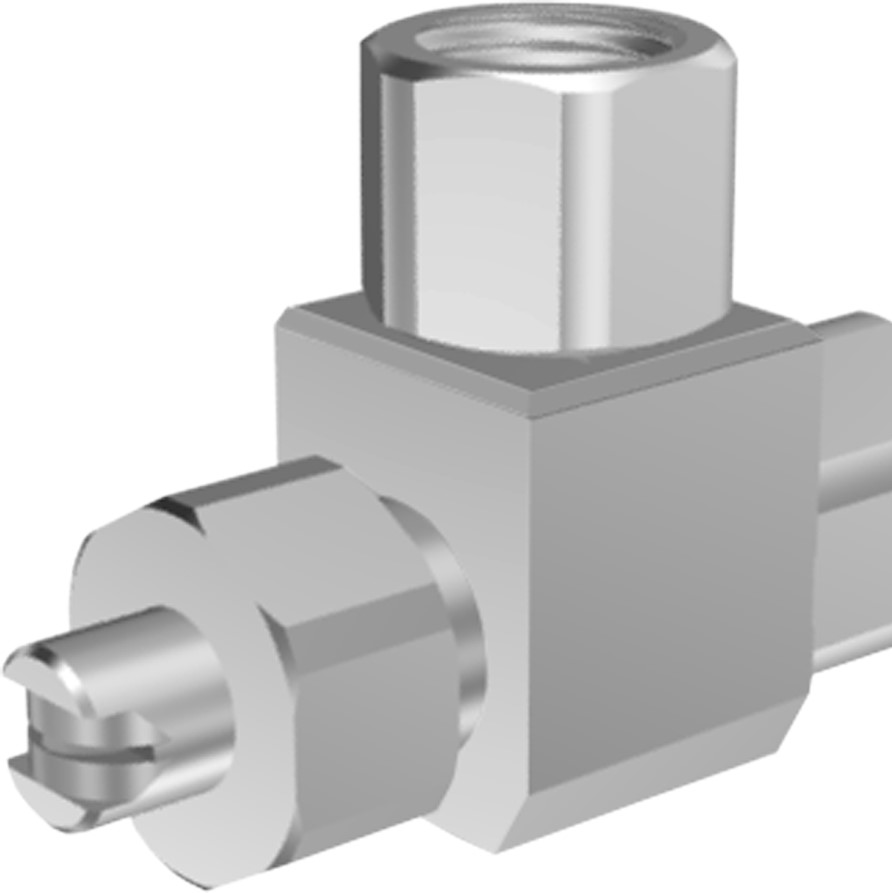

Hydraulic nozzle

The hydraulic nozzle sprays one liquid such as water.

The hydraulic nozzle is the most commonly used, and various spray patters are available.

In using the hydraulic nozzles, pressure ranges can be from less than 0.1Mpa to more than 50MPa. Considering this point, you have to select an appropriate nozzle, depending on the purposes and conditions.

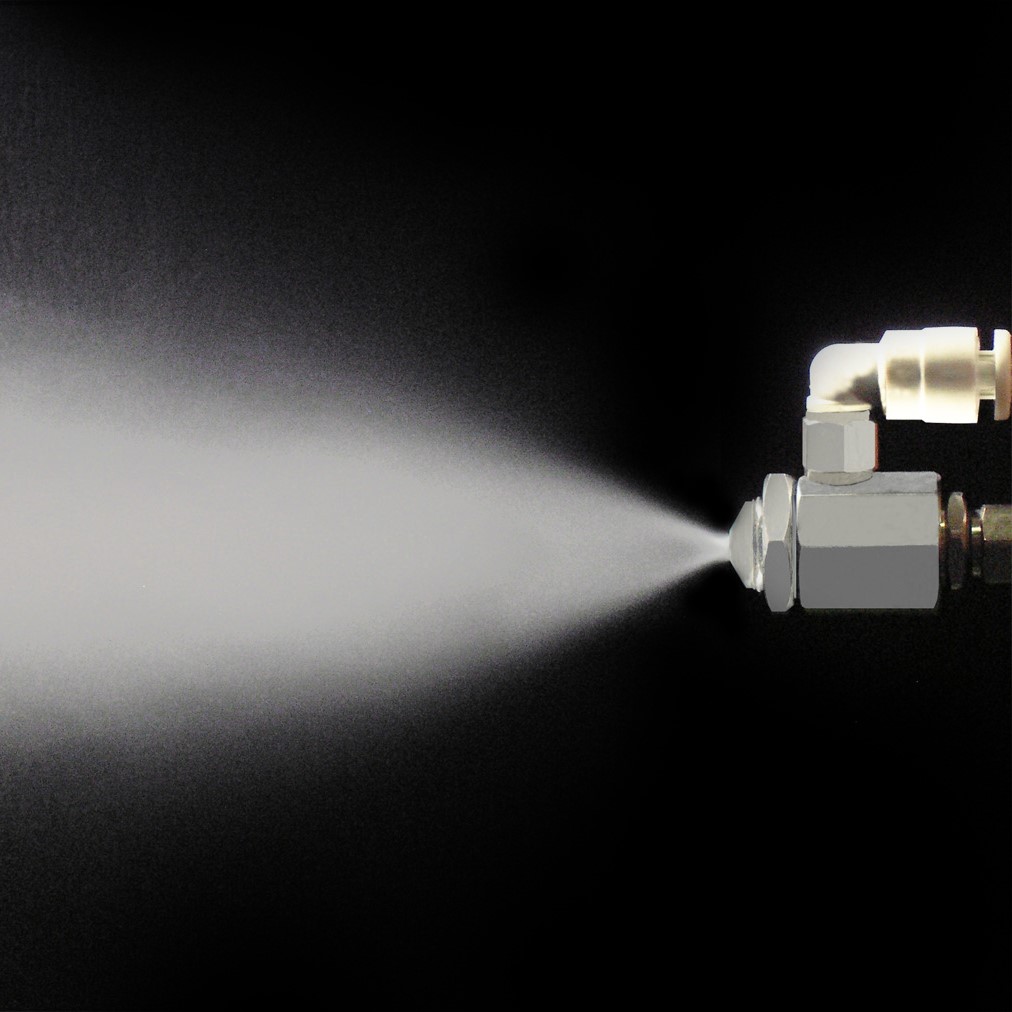

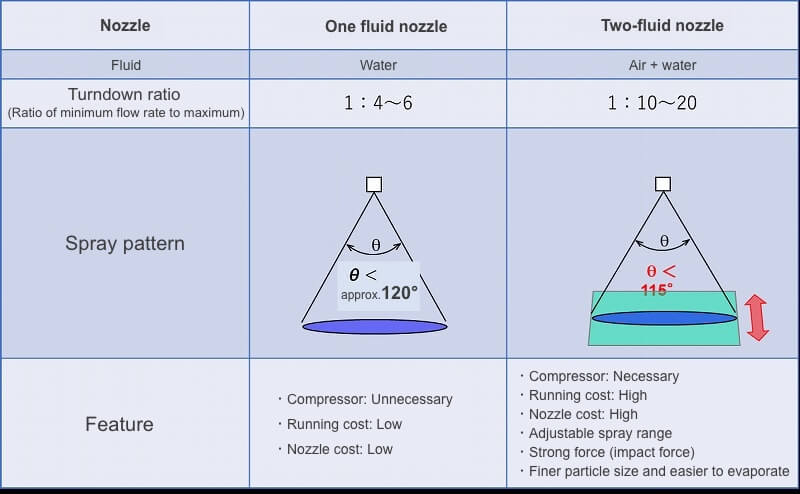

Comparison of hydraulic nozzle with two-fluid

*Turndown is a ratio from minimum flow rate to maximum

Turndown is shown as 10 times in the minimum flow as 1L/min and the maximum one as 10L/mins.

The above chart shows a comparison of the hydraulic nozzle with a two-fluid.

Although the hydraulic nozzle turndown ratio is a small range, the spray pattern is wider, which is one of the hydraulic nozzle's specialty. That shows that the spray angle changes by pressures.

The spray angles have to be considered in case of various flow conditions.

Compared with the two-fluid nozzles, running costs in the hydraulic nozzle is much lower since an air compressor is not required. Additionally, the hydraulic nozzle is cost-effective.

References

Basic knowledge and selection method in two-fluid nozzle

Selection method of hydraulic spray nozzle

Selection method of hydraulic spray nozzle

Equipment check

Check a equipment specification before selecting a hydraulic nozzle.

Pressure and flow rate to the spray nozzle all depend on a pump specification and piping.

Checking the spray nozzle mounting shape. The hydraulic nozzle mounting shape such as threading size depends on a header size.

An internal flow rate plays an important part in the header size. For more details, check the below link for a correlation of the header size and the flow rate

References

Correlation of the header size and the flow rate

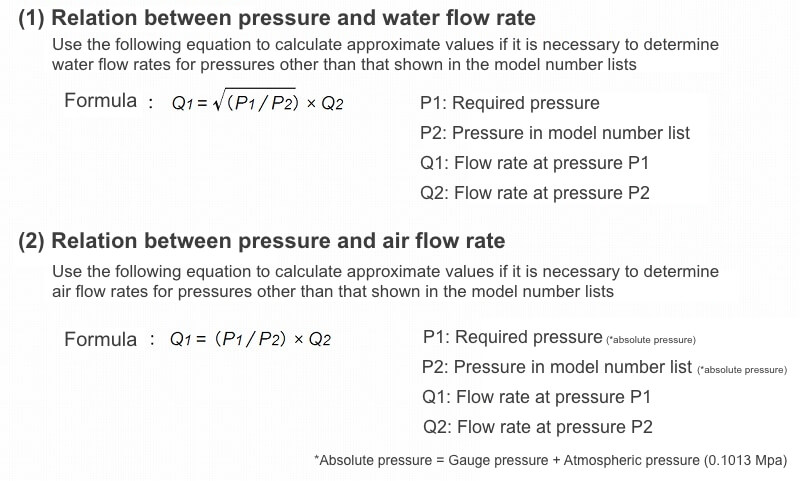

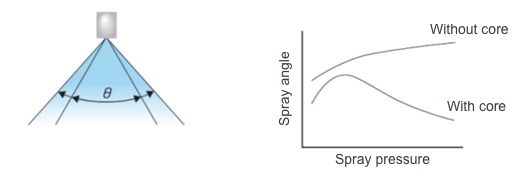

Spray angles can change in each nozzle model, which is different from a flow rate increase by a pressure increase.

Note a spray angle change especially when there are any flow rate ranges.

A spray angle in some nozzles with an insert core such as full-cone nozzle

increases up to certain pressure and decreases afterwards, which is different from the spray angle increase by pressure increase in general.

Check conditions

Check the condition in which the spray nozzle is used.

A material for the optimized hydraulic nozzle depends on a surrounding

temperature and a liquid characteristic.

There might be a clogging concern in case of any foreign materials included in the liquid.

If the foreign material size is informed, we will be able to propose a spray nozzle with the minimum flow passage considered.

Select a specification of the hydraulic nozzle

Select the pressure, flow rate, spray pattern and spray angle

in 1 piece of spray nozzle.

Note that, if any particle size is requested, the nozzle performance might not be sufficient ,depending on some conditions such as pressure and others.

In case multiple hydraulic nozzle are lined up in a row, contact us with the total flow rate and a width of sprayed object.

Selections of hydraulic nozzle and model

Referring our catalogue, select a spray nozzle type based on the spray pattern.

After selecting the hydraulic nozzle from flat, full-cone, hollow-cone, straight, curtain and others, check the flow rate and spray angle under the specified pressure.

Check the minimum flow passage on our catalog if necessary.

You can select the nozzle model by following the above processes.

Contact us for the further information

We can supply some standardized hydraulic nozzles with a short lead time

because of our inventory base system. To meet your requests, our customizations are also available.

References

hydraulic nozzle types